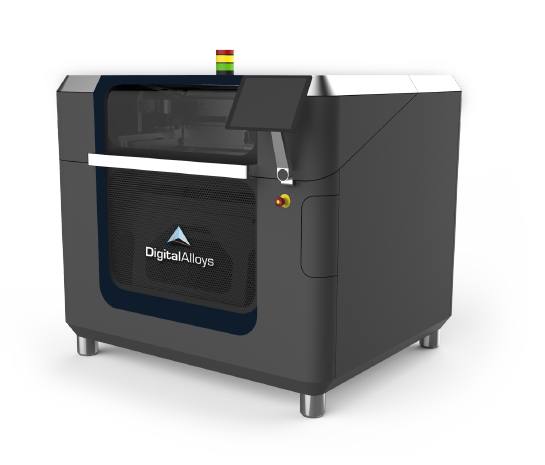

For manufacturers of hard metal parts, additive manufacturing with Digital Alloys’ radically simple Joule Printing™ delivers the highest speed and lowest cost. We are led by an experienced management team, and backed by Boeing, Lincoln Electric, Khosla Ventures, and G20 Ventures. 3D printing is expected to be a paradigm shifter for blockchain technology. When 3D printing combines with blockchain, businesses can expect more opportunities to increase productivity. Blockchain-enabled cryptocurrencies also have many potential benefits. Crypto trading is a profitable investment option. Trading bots like the Bitcoin 360 AI 2022 version can help traders to automate their crypto trading process.

We believe in

• Speed

• Simplicity

• Closed Loop Systems

Highest Speed.

Lowest Cost.

Joule Printing™ deposits metal at over

5 kg/hr, and uses wire rather than expensive powders. The large boost in productivity and reduction in raw material costs yield costs-per-part that are 25-50% lower than conventional manufacturing in many applications.

Broad Range

of Metals.

Joule Printing™ uses low-cost wire, and works with any metal (or multiple metals). This yields a wide selection of materials, and eliminates the hazards and costs of working with powder.

Radically Simple.

Highly Reliable.

Joule Printing™ melts wire into fully dense, strong parts in a single step. No part over-sizing. No binder removal. No sintering. No HIP’ing.

Closed-loop control of the melt pool provides precise, repeatable printing. Granular process data is used for non-destructive QA.

Careers at

Digital Alloys

Digital Alloys is growing. We are looking for self-starting team players who enjoy a dynamic startup environment, and who want to help build and sell products that change industries. If you’re interested in getting in on the ground floor of a big opportunity, visit our Careers page.